What is Playdough (Play-Doh)?

A simple mixture of water, salt, and flour serves as the base for making a pliable modeling material that has been popular with children since the mid-1950s when a similar mixture was marketed under the brand name “Play-Doh.” It was originally created as a wallpaper cleaner! This colorful, non-toxic, pliable putty continues to be a well-known toy still used in homes and schools today. According to the 2004 patent obtained by Hasbro, the current company that produces the retail version of Play-Doh, it is composed of “water, a starch-based binder, a retrogradation inhibitor, salt, lubricant, hardener, fragrance, and color. A petroleum additive gives the compound a smooth feel, and borax prevents mold from developing.”1 These additional ingredients set the retail version apart from the result that one gets just mixing proportioned amounts of flour, salt, and water. Homemade playdough rarely turns out as high quality of a modeling putty when compared to the retail brand, but it is possible. Children often enjoy the tactile experience of making shapes and models out of playdough. They like to cut it, mold it, roll it, and play with it. High quality playdough can be used in free play sensory centers, or as a tool for forming letters, numbers, shapes, or even models of animals, land formations, and building structures.

What is a Chemical Engineer?

“Chemical engineering is the branch of engineering that deals with chemical production and the manufacture of products through chemical processes. This includes designing equipment, systems, and processes for refining raw materials and for mixing, compounding, and processing chemicals to make valuable products.”2 In addition, according to the U.S. Bureau of Labor Statistics, “Chemical engineers apply the principles of chemistry, biology, physics, and math to solve problems that involve the use of fuel, drugs, food, and many other products.”3 Chemical engineers play a vital role in the growth and progress of a society and their reach and scope is vast. Some notable achievements of chemical engineering include parallel development of medicines such as vaccines, antibiotics, and dosed medications; energy resources such as the development fuels both petrol and non-fossil fuel based; the development of fertilizers to promote food production; water sanitization techniques and additives for clean, potable water; as well as the development of materials such as plastics and polymers.

As students learn the role of a chemical engineer, they will practice being chemical engineers by working on the problem of creating a high-quality playdough using a systematic process with recorded notes and observations.

What is Dough?

Dough is a thick, pliable paste made of flour derived from grains, legumes, or starchy vegetables and a small amount of water and/or other liquid. Many food products are made from dough, including breads, noodles, pasta, cookies, cakes, crackers, biscuits, pancakes, waffles, muffins, pies, tortillas, and so on. The process of making dough starts simply with a mixture of flour and water with additives such as salt, leavening agents (e.g., yeast or baking soda), sugars, oils, and fats. Depending on what you are trying to make, variations in ingredients and preparation methods will lead to different end products.

What is Flour and How is it Made?

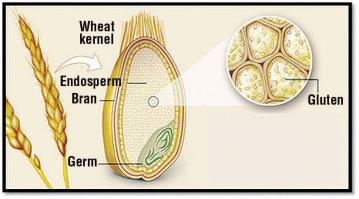

Flour is a powder derived from finely ground cereal grains or starchy roots and vegetables (e.g., potatoes). Cereal grains are the seeds of grassy plants such as wheat, rye, rice, or corn to name a few popular varieties. When a cereal plant has reached the end of its life cycle, the leaves and stalk turn brown and seed production is complete. The seed or grain includes three parts: bran (the fiber rich outer skin), endosperm (the starch and protein rich food for the germ), and the germ (the part that will sprout and grow into a new plant).4 These grains are harvested in large quantities and go through a milling process that includes purification (the removal of all foreign matter, husks, stems, and leaves). A variety of sifting technologies have developed over time to improve the purification process. The grains are then prepared for grinding by adjusting the moisture content of the grain to assist in separating the bran from the endosperm. Whole grains are ground using all parts of the grain, while refined flour is produced using just the endosperm. The bran and germ do have nutritional value, but the germ is especially removed to preserve the flour longer and prevent it from becoming rancid during storage and transportation due to oxidization of the polyunsaturated fats in the germ. Whole grain flours will last up to three months if stored in a cool, dry location, while refined flour can last a year. Refined flours lose most nutrients during the refining process, so refined flour is often “enriched” by having the iron and B vitamins (folic acid, riboflavin, niacin, and thiamine), and sometimes calcium and vitamin A, added back to the flour after the grinding process.5 After the grains are ground to a fine powder through various grinding and sifting machinery, they are chemically bleached white often using bleaching or oxidizing agents such as benzoyl peroxide or chlorine gas. The bleaching process also gives the flour a finer, softer texture in addition to the whitening.

Each type of flour, depending on the source of the grain and how it is processed, has different nutritional values as well as cooking or baking characteristics.

Figure 1 The internal composition of a grain of wheat.

What are the Differences between Various Types of Flour?

There are hundreds of varieties of flour, and wheat flour is one of the most prevalent. Protein content varies depending on the type of flour. High-protein wheat varieties (10 to 14 percent protein) are classified as "hard wheat”, while low-protein wheat varieties (5 to 10 percent protein) are classified as "soft wheat." Higher protein correlates to more gluten in wheat flours. Some of the most common will be listed here, although this list is not comprehensive.

All Purpose Flour: Made from a blend of high gluten hard wheat and low gluten soft wheat. Wheat gluten levels can vary due to the season the wheat was grown, or by using different varieties of wheat. This flour is made only using the endosperm of the grain. All-purpose flour is refined and often enriched by having the stripped nutritional values added back at the end of the refining process. The protein content is 10% to 12%.

Wheat Flour: Made from the whole grain of wheat and has a higher nutritional and fiber content, but shorter shelf life. Often produces heavier breads. The protein content is like all-purpose flour at 10% to 12%.

Self-Rising Flour: This is all-purpose flour, but has salt and a leavening agent, such as baking soda added during the manufacturing process. Used as a convenience for baking without yeast, but not recommended for playdough due to the added ingredients.

Cake Flour: Made from soft wheat which has a higher starch but lower gluten levels. This produces a lighter, crumbly texture. The protein content is usually 5% to 8%.

Bread Flour: Opposite of cake flour. Has a higher gluten level, but less starch and is made from hard wheat. The extra gluten helps trap carbon dioxide gas as the bread bakes, producing a tougher and chewier texture. The protein content is usually 12% to 14%.

Semolina Flour: Made from a coarsely ground, high gluten durum wheat variety and is used for making pasta.

Gluten Free Flours: Gluten free flours contain little to no wheat and are produced from other plants. Almonds, coconuts, peanuts, potatoes, rye, soy, oat, rice, and corn are a few examples of sources of gluten free flours. Gluten free flours may also be a blend of several non-wheat sources. Protein content for gluten free flours can vary depending on the source, with some varieties having as much protein as bread flour without the gluten.6

What are the Molecular Components of Flour?

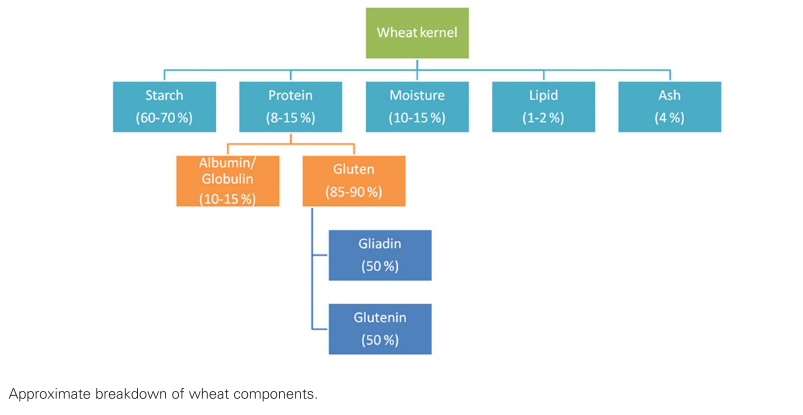

“The wheat kernel contains 8%–15% of protein, of which 10%–15% is albumin/globulin and 85%–90% is gluten. Gluten is a complex mixture of hundreds of related but distinct proteins, mainly gliadin and glutenin. Different wheat varieties vary in protein content and in the composition and distribution of gluten proteins.”7

Figure 2 The composition of a grain of wheat broken down into starch, protein, moisture, and other components.

As you can see in Figure 2, most of the wheat grain is starch, protein (in the form of gluten), and moisture. The percentages vary depending on the variety and growing conditions of the harvested wheat.

What is Gluten?

Gluten is protein found in flour. It contributes to the elastic nature of flour dough in cooking. For example, making Asian noodles or bread calls for flour with high gluten content for the chewiness, while making cake calls for flour with low gluten content for fluffiness. Kneading can help gluten molecules align and stretch out in the dough such that a molecular network can form and improve elasticity of dough. Wheat-based flour, as you can see in Figures 1 and 2, contains two dominant proteins – Gliadin and Glutenin. When these two proteins encounter water, they bond together and change shape. This creates an elastic network called gluten. This gluten network can trap gases in the baking process. The more the gluten, the higher the protein content and the heavier the bread. In dough, starch molecules and gas bubbles, usually aided by a leavening agent like yeast or baking soda, causes the dough to rise.8 In this unit, students will explore the gluten content of flour and see how it changes the texture and elasticity of playdough.

What is Starch?

The four classifications of carbohydrates are monosaccharides, disaccharides, oligosaccharides, and polysaccharides. Monosaccharides are simple, single monomer sugars that include glucose, fructose, and galactose. Disaccharides are a pair of monomers linked together by a covalent bond known as a glyosidic linkage and include lactose, sucrose, and maltose. Oligosaccharides contain 3 to 10 linked monomers, and polysaccharides contain more than 10 linked monomers. Starch is a polysaccharide, a polymer with a long molecular structure, and therefore can act as a binder to keep molecules together.9

Almost all types of green plants produce starch that serves as a storage for energy. Fruits, seeds, and tubers also store starch in preparation for the next growing season. When extracted, starch looks like a fine, white, semi-crystalline powder. It is also one of the major components in flour. Polysaccharides have a lot of hydroxyl (-OH) groups that can form hydrogen bonds with water, and therefore it can hold on to water molecules, keeping playdough moist.

Why Add Water to Flour to Make Dough?

Water is responsible for hydrating the starch, as well as hydrating the proteins to trigger the natural chemical processes in forming gluten. It is an essential ingredient in making dough, as without water these natural processes would not occur. In making playdough, one must carefully control the ratio of flour to water. Too much water will produce runny dough that will not hold its shape nor form gluten properly, while too little water will produce a sticky paste. Hydration levels are important in baking, and even the room humidity can influence dough quality even when consistently using the same proportioned measurements. For our playdough, humidity should not play a huge factor in the dough quality.

A baker’s rule of thumb for dough hydration is around 65%. This means that the weight (more on using weight rather than volume later) of the water should be around 65% of the weight of the flour and other ingredients. For example, I used 200 grams of flour and 100 grams of salt, and 65% of that is 195 grams of water (I rounded up to 200 grams of water for the playdough in this unit). Some experimentation might be necessary here, as the type of flour and even the quality of water (hard or soft, any added minerals or chemicals) can affect dough hydration. Since we are not working with yeast or other leavening agents, it is okay to add a little more water or a little more flour to make minor adjustments. Making dough is a tactile experience (part of why children love it) and eventually you will be able to tell when the dough is ready because it will feel just right – not too sticky, not too dry, not too wet.

What is the Role of Salt in Dough?

Salt in the dough helps strengthen the gluten bond by affecting the electrostatic interactions. The gluten proteins naturally repel one another, but the chloride ions in salt help them overcome that repulsion and stick together. This results in a dough that is less sticky or tacky. Salt also plays a beneficial role in preventing or reducing the growth of mold, therefore acting as a preservative.10

How Does Heat Affect the Formation of Dough?

Heating, or cooking, the dough will help the physical and chemical processes be faster and more complete. Starch becomes soluble in water when heated. When the granules swell and burst, the semi-crystalline structure is lost and the smaller amylose molecules start leaching out of the granule, forming a network that holds water and increasing the mixture's viscosity. This causes the starch to gelatinize. Heating provides the additional energy to make insoluble grains of starch soluble in water. There are plenty of “no cook” playdough recipes to be found online, some use heated water. Others rely on a lot more mixing and kneading. In my experience, I have found the “no cook” playdough recipes to be less reliable when making (often too runny or too firm) as well as produce an inferior playdough (too grainy or does not last as long).

Why Do We Knead the Dough?

Kneading the dough is a process that involves massaging, stretching, and folding the dough to create a strong gluten matrix. When the dough ingredients are first mixed, the proteins are mangled and knotted in no particular order. But as the dough is kneaded, the proteins line up to form long chains of gluten molecules, creating a matrix within the dough itself. The process of kneading helps combine the ingredients as well as improve the gluten matrix.

Why Do We Add Cream of Tartar?

Cream of Tartar (it is a white powder, not a cream) is an acidic compound that grapes produce as they ferment. It is often used in baking as a leavening agent when combined with baking soda to produce carbon dioxide bubbles. In fact, baking powder is a mixture of baking soda and cream of tartar. It is slightly acidic, and because of this, it affects the gluten structure of the playdough to make it more elastic. Tartaric acid acts as an emulsifier, so it helps prevent any added oil from separating. It also prevents the salt from crystalizing, resulting in a smoother, softer playdough. I have found this to be an essential ingredient to make long-lasting, brand quality playdough. If cream of tartar is unavailable (usually found in grocery store spice section), baking powder or 2 teaspoons of lemon juice might be a fair substitute.

Why Do We Add Oil to the Dough?

Adding a small amount of oil to the dough reduces elasticity of the gluten by restricting longer molecule development, but it also improves the moisture-retaining properties of the playdough. I find adding a small amount of oil produces better overall playdough that is less sticky, yet still more elastic than playdough made without cream of tartar. Any oil will do, but I prefer a scented lavender oil as this gives the playdough a nice fragrance.

Measurement Tips

While it is common to measure dry and liquid ingredients by volume, such as cups or liters, I have found that it is far more accurate to base measurements on weight. I use an inexpensive postal scale that can display weight in grams. Having students use measuring cups is a good practice, but there can be a great deal of discrepancy between any two or more student-measured cups of flour, usually due to air pockets and how well students packed down the flour. Measuring by weight eliminates this problem and is far more accurate.

What is My Favorite Playdough Recipe?

If you search the internet for playdough recipes, you might find hundreds of variations – many claiming to be the best. My favorite recipe does involve cooking the playdough, even though that may seem daunting to do with a class of first graders. With a simple hot plate, saucepan, and appropriate precautions and safety discussion, this should be a low-risk activity that will also greatly excite and interest your students.

My favorite recipe:200 g flour (about 2 cups)100 g salt (about 1 cup)200 g water (about 1 cup, add food coloring to water)10 g Cream of Tartar (about 2 teaspoons)10 g Lavender Oil (about 2 tablespoons)

Simply mix all ingredients together over medium heat. Stir constantly, insuring dough does not burn on bottom of pan. After five to seven minutes of stirring what seems to be a soup, the dough will rapidly begin to coalesce. Eventually you will have a ball of dough stuck to the spoon. Keep stirring until almost all the dough has separated from the pan and let cool for a few minutes. While it is still warm and soft, knead the dough to help form a strong gluten matrix and nice, stretchy playdough.